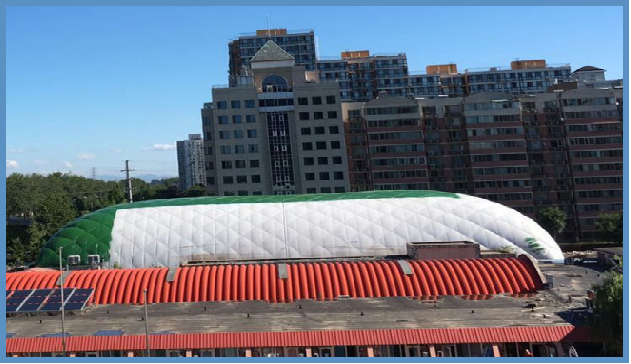

With the rapid development of China's national economy and the comprehensive acceleration of the construction of municipal infrastructure, especially environmental protection projects such as sewage treatment plants are increasing. Among them, an appropriate number of anaerobic tanks, sludge concentration tanks, and biological flocculation tanks have been built in Around the residential area, the environment, appearance, and smell of sewage in the sewage pond directly affect people's life and health. In order to care for the people, build a harmonious society, and create a beautiful environment, many city management departments have now asked about the sewage in the sewage pond. The treatment tank is capped for waste gas collection and management.

Features of special membrane for sewage tank:

1. High-strength low-gauze polyester and high-quality PVC coating

High-strength low-yarn polyester yarn has the characteristics of high tensile strength, good flexibility, lightness and toughness, as well as tearing, folding resistance, abrasion resistance, oil resistance, non-toxic hygiene, good air tightness and so on. High-quality PVC coating improves the appearance characteristics of traditional coating materials, has excellent anti-pollution ability, can persist in long-term cleaning, enhance anti-oxidation function, avoid PVC aging, and extend the service life.

2.UV light curing treatment

Membrane structure environmental engineering membrane material, using advanced UV light curing treatment technology, can improve the field durability of organic coatings and UV absorbers also function as external light filters, which can block harmful sunlight from entering the coating substrate . Useful aging resistance function of organic materials can maintain stable physical functions at high and low temperatures, and have chemical stability under acid and alkali conditions, which greatly improves the service life of materials in severe conditions such as strong corrosion, strong acid and alkali, and smoke.

3. Sewage and liquid chemical treatment

The environmental engineering film material is selected from the high-quality low-yarn high-density polyester silk adhesive layer to participate in excellent and efficient anti-capillary and anti-mildew additives, which completely eliminates the mold caused by lateral seepage, drops and other phenomena.

Operational planning

1. Collection and storage of odors in the fields of sewage treatment and garbage treatment.

2. Collection and storage of low-pressure corrosive gases in pharmaceutical, chemical, refining, metallurgy and other fields.

The field of gas management is still a relatively new subject in China. Sigma structure is widely used in the sewage tank capping project. The traditional method of sewage tank capping in our country has limited the gas collection due to the shortcomings of anti-corrosion. The cover of the membrane structure with various shapes and excellent light transmission functions is worthy of expansion and implementation due to the ambition of engineering practice.

Shenzhen Sigma is a professional service company mainly engaged in the design, processing and installation of architectural membrane, tensile membrane structure, sewage tank membrane cover, air membrane building, space membrane structure and cable membrane structure. The company attaches importance to quality first, safety, efficiency and innovative ideas.