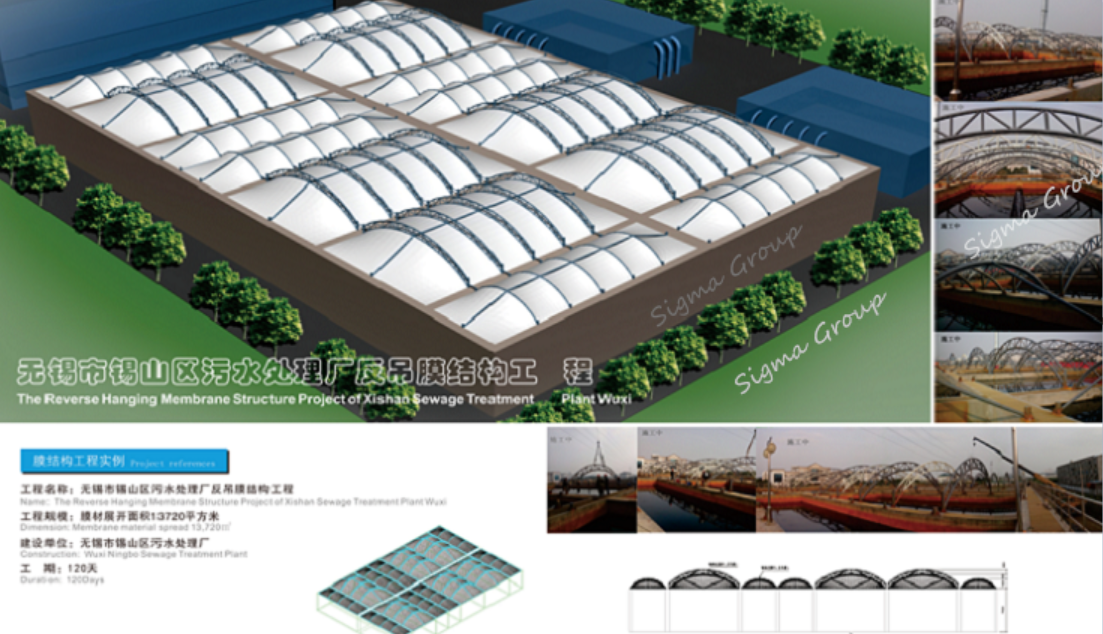

#Sewage treatment plant anti-hanging membrane structure project#

The so-called reverse hanging membrane is the method of reverse hanging the membrane material of the sewage tank and the external steel structure to seal the waste odor gas in the sewage tank to prevent the waste odor gas from the sewage tank from spreading and polluting the surrounding environment.

The ingenious feature of the reverse-hanging membrane structure project of Wuxi Xishan Sewage Treatment Plant is the "reverse-hanging", which uses a strong anti-corrosion sparse anti-corrosion dilute carbon membrane material to cover the exhaust gas, and the steel structure hangs the membrane outside. This not only exerts the anti-corrosion performance of the anti-corrosion dilute carbon film material, but also fundamentally solves the corrosion problem caused by the contact of the steel structure with corrosive gases.

Features of anti-hanging membrane for sewage tank:

1. Corrosion resistance;

An energy-saving membrane with strong corrosion resistance is used to cover the exhaust gas, and the membrane is suspended on the outside by a steel structure. This not only exerts the anti-corrosion performance of the energy-saving membrane, but also fundamentally solves the corrosion problem caused by the contact of the steel structure with corrosive gases. Therefore, the steel structure can be designed according to the anti-corrosion level of the ordinary building steel structure, with a 50-year The service life of the steel structure gives play to the performance of the steel structure, and the perfect combination of the structural framework and the covering material is realized. Service life: 15 years for membrane part and 50 years for steel structure part.

2. Thermal insulation;

The pool body covering material adopts double-layer environmental protection and energy-saving film, which has good anti-aging, corrosion resistance, heat resistance, cold resistance and scratch resistance.

3. Energy-saving film;

Non-toxic, non-odor, non-radioactive, high temperature resistance, low temperature resistance, flame retardant, stable chemical properties; long service life.

4. Large span;

Due to the light weight of the membrane material and the high tensile strength, the membrane structure can fundamentally overcome the difficulties encountered by traditional structures in large-span (no support in the middle) buildings, and is suitable for large-span pools.

5. Easy to install;

The steel structure production and the processing of the membrane body are carried out in the factory, and the processing quality is reliably guaranteed. The on-site installation time is short, which reduces the occupation of the site. In particular, the old pool body reconstruction project can adopt the overall structure hoisting, without affecting the operation of the equipment inside the pool body.

6. Self-cleaning;

The membrane material has extremely high non-adhesiveness, and the surface is not only difficult to adhere to dirt and dust, but can be kept clean as new for a long time through the washing of rainwater.

7. Economical;

The membrane structure has unique advantages on the covering of the super-span pool body.

8. Tightness;

All membrane materials are welded by hot melt, and the on-site hot melt welded "secondary node seal" between the membrane sheets installed on site not only ensures the sealing of the cover, but also ensures that the internal corrosive gas can be prevented from corroding the steel structure.

9. Convenient for maintenance;

Due to technological requirements, the equipment needs to be inspected and maintained regularly. It can be solved by preserving doors and passages on the side membrane (membrane structure sealed vertical curtain doors or plastic steel windows). In sewage treatment, due to engineering improvements or processes As required, a cover plate is required to close the sewage tank. It can not only prevent the volatilization of sewage in the sewage tank from polluting the surrounding environment, but also allow workers or machines to perform construction on the surface of the cover.

10. Convenient for pipeline docking;

It is convenient for sealing connection with the pipes of the field equipment: the membrane structure of all the facades can be opened on site as needed, and the air tightness can be restored by the on-site hot-melt welding.

11. Beautiful appearance;

The steel-supported anti-hanging membrane structure has all the characteristics of modern architectural membrane structures, elegant and beautiful in shape, and good in self-cleaning performance. Due to the PVDF self-cleaning coating, it can effectively reduce the adhesion of the dust on the surface of the membrane material. It can be effectively cleaned by natural rainwater. The anti-fouling ability of the sewage treatment plant is far greater than other traditional covering materials. It keeps its bright look and feel for a long time and has good optical properties.